Fuels

Click on a yellow box below to jump to a topic

Introduction of E10 Fuel Volatility Ethanol Synthetic Fuels Other Fuels Operating Problems Octane

Fuel Additives

The FBHVC was instrumental in testing aftermarket lead replacement additives for unleaded petrol and corrosion inhibitors for ethanol containing petrol and historically endorsed several fuel additives.

The FBHVC continues to support the use of aftermarket additives for lead replacement and corrosion protection where appropriate.

Fuel additive approval requires extensive performance and no-harm testing to validate performance claims and safe use in classic and historic vehicles. The FBHVC has therefore decided to cease endorsement of aftermarket fuel additives as it is difficult keep up to date with fuel additive formulation and performance claim changes and expensive to test their respective performance in classic and historic vehicles.

The fuel additive aftermarket is mature and many classic and historic vehicle owners have good experience of using these additives to protect their vehicles from damage.

The FBHVC recommends that this experience is shared via member clubs to their membership to help select appropriate fuel additives. The FBHVC will continue to recommend that lead replacement and corrosion inhibitor additives are considered by FBHVC members but will not make specific manufacturer recommendations or endorsements.

The FBHVC will continue to provide advice on fuel quality to member clubs and their members including the appropriate use of fuel additives to protect classic and historic vehicles.

Guidance on the use of Rebated diesel (red diesel) in classic and historic agricultural equipment

The Government has announced changes in the use of rebated red diesel (dyed gasoil) from April 2022. https://www.gov.uk/government/publications/reform-of-red-diesel-entitlements/reform-of-red-diesel-and-other-rebated-fuels-entitlement

Historically red diesel is diesel used mainly for off-road purposes, such as agriculture, forestry, fisheries, rail, construction industry, or to power drills for oil extraction. Government figures show that it accounts for around 15% of all the diesel used in the UK and is responsible for the production of nearly 14 million tonnes of carbon dioxide a year. Red diesel used in the construction and infrastructure building sectors was also estimated to have caused 7% of nitrogen oxide emissions and 8% of PM10 emissions (a type of fine particulate matter) in London in 2018.?

From April 2022 the use of red diesel has been limited to the following purposes:

- for vehicles and machinery used in agriculture, horticulture, fish farming and forestry. This includes allowing vehicles used for agriculture to be used for cutting verges and hedges, snow clearance and gritting roads

- to propel passenger, freight or maintenance vehicles designed to run on rail tracks

- for heating and electricity generation in non-commercial premises - this includes the heating of homes and buildings such as places of worship, hospitals and townhalls; off-grid power generation; and non-propulsion uses on permanently-moored houseboats

- for maintaining community amateur sports clubs as well as golf courses (including activities such as ground maintenance, and the heating and lighting of clubhouses, changing rooms etc.)

- as fuel for all marine craft refuelling and operating in the UK (including fishing and water freight industries), except for propelling private pleasure craft in Northern Ireland

- for powering the machinery (including caravans) of travelling fairs and circuses

The measure will also extend fuel duty to biodiesel, bioblends and fuel substitutes used in heating, applying the rebated duty rate to non-commercial heating and the full rate of duty to commercial heating.

The Government has also recently added further clarification of these measures in an answer to a parliamentary question on 22 February 2022, that:

“The Chancellor confirmed at Spring Budget 2021 that the Government will remove the entitlement to use red diesel from most sectors from April 2022, other than for agriculture and a limited number of other users. This will help to ensure fairness between the different users of diesel fuels and that the tax system incentivises the development and adoption of greener alternative technologies.

Agricultural vehicles will be entitled to run on rebated fuel after April 2022 for purposes relating to agriculture, horticulture, forestry and fish farming. They will also be able to use rebated fuel when cutting verges and hedges that border a road, clearing snow, gritting, and clearing or otherwise dealing with flooding.

The activities accepted as purposes relating to agriculture, horticulture and forestry are defined in HMRC Excise Notice 75. The Government considers that running or participating in events which provide information and education that benefit agriculture are purposes relating to agriculture, and this includes taking part in charitable activities that promote these industries. Examples of such events are agricultural shows, ploughing matches and charity tractor runs. HMRC will be updating Excise Notice 75 accordingly. Rebated fuel can also be used to travel to and from where the vehicles or machines are to be used for these activities.

The legislation for kerosene remains unchanged.

It should be noted that red diesel is not only dyed red but also contains several invisible chemical markers that can be measured at low levels of dilution. It is therefore important to make sure that any bulk storage tanks and vehicles/machinery switched to operating on road (white) diesel have their fuel tanks and fuel systems thoroughly flushed to ensure there are no remaining traces of the red rebated diesel.

Latest News

Our fuels specialist Nigel Elliott has received some new questions with regards to ethanol and the use of E10 in historic vehicles and his thoughts are as follows:

Further advice on ethanol with respect to fuel additives.

Ethanol and aftermarket fuel additives

There are three key areas of concern with Ethanol compatibility with historic and classic vehicle fuel systems:

- Corrosion of metal components

- Elastomer compatibility - swelling, shrinking and cracking of elastomers (seals and flexible pipes) and other unsuitable gasket materials

- Air/fuel ratio enleanment

Corrosion of metal components

Ethanol has increased acidity, conductivity and inorganic chloride content when compared to conventional petrol which is essentially neutral and can cause corrosion and tarnishing of metal components under certain conditions. These characteristics are controlled in the ethanol used to blend E5 and E10 European and UK petrol by the ethanol fuel specification BS EN15376 in order to help limit corrosion.

Corrosion inhibitor additives can be very effective in controlling ethanol derived corrosion and are recommended to be added to ethanol in the BS EN15376 standard. It is not clear if corrosion inhibitors are universally added to ethanol for E5 and E10 blending so as an additional precaution it is recommended that aftermarket corrosion inhibitor additives are added to E5 and E10 petrol.

These aftermarket ethanol corrosion inhibitor additives often called ethanol compatibility additives are usually combined with a metallic valve recession additive (VSR) and sometimes an octane booster and have been found to provide good protection against metal corrosion in historic and classic vehicle fuel systems.

Elastomer compatibility

As the ethanol molecule is smaller and more polar than conventional petrol components, there is a lower energy barrier for ethanol to diffuse into elastomer materials. When exposed to petrol/ethanol blends these materials will swell and soften, resulting in a weakening of the elastomer structure. On drying out they can shrink and crack resulting in fuel leaks.

Some aftermarket ethanol compatibility additives claim complete protection for operating historic and classic vehicles on E10 petrol. The FBHVC is not aware of, or has tested any additives that claim complete fuel system protection with respect to elastomer and gasket materials for use with E10 petrol. The FBHVC therefore recommends that elastomer and gasket materials are replaced with ethanol compatible materials before operation on E10 petrol.

Air/fuel ratio enleanment

Ethanol contains approximately 35% oxygen by weight and will therefore result in fuel mixture enleanment when blended into petrol. Petrol containing 10% ethanol for example, would result in a mixture-leaning effect equivalent to approximately 2.6%, which may be felt as a power loss, driveability issues (hesitations, flat spots, stalling), but also could contribute to slightly hotter running. Adjusting mixture strength (enrichment) to counter this problem is advised to maintain performance, driveability and protect the engine from overheating and knock at high loads.

Modern 3-way catalyst equipped vehicles do not require mixture adjustment to operate on E10 petrol because they are equipped with oxygen (lambda) sensors that detect lean operation and the engine management system automatically corrects the fuel mixture for optimum catalyst and vehicle operation.

Operating classic and historic vehicles on E10 petrol

If you should decide to make the necessary vehicle fuel system modifications together with the addition of an aftermarket additive to operate your classic or historic vehicle on E10 petrol. The FBHVC strongly recommends that you regularly check the condition of the vehicle fuel system for elastomer and gasket material deterioration and metallic components such as fuel tanks, fuel lines and carburettors for corrosion. Some plastic components such as carburettor floats and fuel filter housings may be become discoloured over time. Plastic carburettor float buoyancy can also be affected by ethanol and carburettors should be checked to ensure that float levels are not adversely affected causing flooding and fuel leaks.

Ethanol is a good solvent and can remove historic fuel system deposits from fuel tanks and lines and it is advisable to check fuel filters regularly after the switch to E10 petrol as they may become blocked or restricted. If your vehicle is to be laid up for an extended period of time, it is recommended that the E10 petrol be replaced with ethanol free petrol which is available from some fuel suppliers. Do not leave fuel systems dry, as this can result corrosion and the shrinking and cracking of elastomers and gaskets as they dry out.

Setting the Scene

When it comes to fuel to provide the motive power which enables us to enjoy our historic vehicles, there is perhaps no more apt description than “the one constant is change”. Many owners and drivers of historic vehicles resist change as a matter of course; to some extent it goes with the territory of enthusiasm for classic and historic vehicles, which by definition are from an earlier time, and which many owners quite reasonably do not want to modify or update. It is part of the charm of our hobby that our vehicles should retain as many of their original characteristics as possible. When it comes to road fuels, however, our ability to resist change is much more restricted by the realities of the availability and distribution of fuel. Clearly if it is desired to drive an historic vehicle for a distance of 250 miles, for example, but the fuel tank capacity provides a maximum range of 200 miles, it will be necessary to refuel part-way through the journey. Therefore if a hypothetical situation existed in which special fuels were available for historic vehicles, they would have to be reasonably available all over the UK in order to permit their unrestricted use.

Unfortunately, the reality is that none of the normal fuel retailers is prepared to provide special fuels for a sector of the motoring public which at best represents perhaps one tenth of one per cent of the number of vehicles on the roads of Britain, and to make this type of fuel available from most of the retail outlets in the country. Demand would be almost non-existent in the winter months, and very limited even in the summer months. Commercially, the scenario of special fuels for historic vehicles at any meaningful level of availability is a non-starter. Therefore it must reluctantly be accepted that as owners and drivers of historic vehicles, we have to use the available fuels, and make adjustments or small changes to our historic vehicles to enable them to operate satisfactorily on the changing retail fuels, if continued use is to remain a reality.

The changing nature of fuels

Looking back over a quarter of a century or perhaps longer, there have been changes to:

- Octane quality: loss of “two star” petrol in 1989-1990

- Lead in petrol: withdrawal of leaded petrol at the end of the twentieth century

- Boiling characteristics of petrol (also called volatility): progressive increase in the use of very volatile components in the fuel blend

- Sulphur content: reduction to trace levels (10 mg/kg) denoted sulphur free in 2009

- Blending of biofuels:

- Use of ethanol in petrol: initially at 5% volume, increasing to 10% volume in September 2021, although a 5% volume high octane protection grade will still be available.

- Use of biodiesel in diesel: up to 7% volume FAME

- Synthetic fuels: announcements of pilot projects to manufacture liquid fuels in 2020 that can run in internal combustion engines made from hydrogen from water and carbon capture from the atmosphere.

The Federation has maintained a watching brief throughout this period and has sought to understand the concerns of its members, to quantify potential problems for older vehicles and to suggest possible remedies where difficulties have been encountered. It is worth looking at a summary of concerns rising from these fuel changes, and Federation actions. Concerns have been expressed by owners and drivers of historic vehicles whenever changes have occurred. Sometimes these concerns have proven to be ill-founded, while on other occasions, there have been examples of real problems which have necessitated action on the part of the owner to prevent damage, or to maintain normal operation, or possibly both. Concerns linked to the fuel changes identified above are discussed below:

Octane quality:

Concerns were expressed about the loss of low octane fuels with, in the view of some, “too much” octane for old engines. Study has shown that this concern is baseless. In effect, it is impossible to have too much octane quality, and older engines can operate very satisfactorily on a fuel with octane quality greatly exceeding their natural requirement.

In the mid 1930s Research Octane Numbers (RON) were around 70 which allowed compression ratios to increase to about 5.5:1. Many 1950s vehicles, for example, probably require no more than 80 RON petrol, if such a product were available, yet will run well on 95 or 97+ RON petrol. Furthermore, most pre-war cars were designed to tolerate even lower octane fuels, yet will also run well on today’s 95 or 97 RON petrol. Octane requirement should therefore be seen as a minimum requirement to ensure the correct operation of the engine. More information on octane is provided in the Operating problems and supplementary information section.

Lead:

The withdrawal of lead from petrol raised very real concerns about engine damage from exhaust valve seat recession (VSR) in older engines with cast-iron cylinder blocks and heads and also aluminium cylinder heads fitted with soft valve seat inserts. The Federation commissioned engine tests to assess the level of protection against VSR provided by fuel additives for use in historic vehicles with unsuitable metallurgy.

Those additives providing the required level of protection were afforded a Federation endorsement, in a scheme which has been a good example of a successful programme of intervention to assist Federation members to overcome potentially harmful side effects from the change in fuel specification inaugurated by the Government.

In addition to defining reliable additive-based treatment options to counter the unleaded threat, the Federation also assisted with information about preventative options in the form of hardened exhaust valve seat inserts to overcome the VSR problem.

Furthermore, the Federation lobbied successfully to secure an EU concession for the sale of leaded petrol in the UK, a concession which survives to this day, although current sales outlets are few in number, and the uptake of the product is quite small. In part, the difficulty of setting up a satisfactory distribution for leaded petrol for the use of historic vehicles, is proof of the general truth that a good distribution system for specialised fuels for historic road vehicles is not a viable commercial proposition.

The use of VSR aftermarket additives is now well established in historic vehicles and due to the changing nature of individual supplier product formulations, it is no longer possible to provide a listing of Federation endorsed additives. VSR additives containing potassium, phosphorous, manganese (MMT) and sodium have all been shown to be effective in preventing valve seat recession under all but the most severe operating conditions. It should be noted that the above VSR additives are not recommended for use in catalyst equipped vehicles and can result in catalyst fouling and oxygen (lambda) sensor failure.

Retailers offering leaded petrol (specification equivalent to the old 4-star petrol):

- As well as being a member of the FBHVC, producers, importers and distributors of leaded petrol must hold a permit from the Secretary of State of Transport in order to comply with Motor Fuel (Composition and Content) Regulations 1999 and subsequent revisions.

- This UK legislation can be viewed at http://www.legislation.gov.uk/

- In order to apply for a permit please contact International Vehicle standards at the Department for Transport at ivs.enquiries@dft.gov.uk

In order to preserve historic and classic vehicle operation on the road and avoid environmental criticism, the Federation encourages all historic vehicle owners to cease using leaded petrol. Those engines that cannot be converted to hardened valve seats can use non-lead based VSR additives which provide adequate protection under all but the most extreme load conditions such as motor racing. The Federation will therefore no longer list fuel suppliers providing lead additives and leaded petrol.

Boiling characteristics (fuel volatility):

Concern that a progressive increase in the use of high volatility blending components in petrol over many decades was identified by the Federation, with many owners of historic vehicles affected by the mystifying but frustrating effects on vehicle performance which can result from the mis-matching of fuel volatility to the needs of older fuel systems. Explanations of the problem were accompanied by simple common-sense solutions which allowed owners to make minimum modifications to their vehicle fuel systems to offset the effect of higher volatility fuels.

The boiling range of petrol has not changed much since the introduction of the first motor vehicles at the end of the 19th century, typically boiling between 30°C and 200°C. Whilst the boiling range has not changed a great deal over the years, the front end of the boiling range has seen an increase in lower-boiling components that increased the vapour pressure of the petrol and the likelihood of vapour bubbles forming in the fuel system causing vapour lock and driveability problems.

Since 1993 petrol volatility has been declining in an effort to reduce evaporative emissions from vehicles. Vapour pressure a measure of volatility is determined at 37.8°C (100°F) and is a good indicator of a fuels propensity to cause vapour locking in older vehicle fuel systems.

| Year | Summer Vapour Pressure (kPa) | Winter Vapour Pressure (kPa) |

| 1985 | 93 | 107 |

| 1988 | 93 | 115 |

| 1993 | 80 | 100 |

| 2000 | 70 | 100 |

Modern summer volatility petrol sold in the UK has a maximum vapour pressure of 70 kPa and in mainland Europe 60 kPa which reflects the difference in summer temperatures. Higher volatility components such as butane are used in the winter, spring and autumn periods as they provide a cost effective, higher octane rating blend component and also help cold starting. A parameter called the Vapour Lock Index (VLI) a calculation using vapour pressure and distillation characteristics which has been developed from vehicle operability data is also applied during the spring and autumn periods to limit vehicle operability issues such as vapour locking.

The seasonal adjustment of petrol volatility is very important for good engine operation all year round, however it can cause problems such as vapour lock in older low fuel pressure vehicle fuel systems. To help owners of historic vehicles it is important to understand how petrol quality is varied in the UK during the year to enable the optimum grade to be purchased for best operation.

The European petrol standard EN228 allows national standardisation bodies to select appropriate volatility and distillation characteristics to suit their local climate conditions.

The British Standard BS EN228 sets out the following vapour pressure grades and dates:

| Spring | Sales of petrol between 16 April and 31 May | 45–100 kPa, VLI limit |

| Summer | Sales of petrol between 1 June and 31 Aug | 45–70 kPa |

| Autumn | Sales of petrol between 1 Sept and 15 Oct | 45–100 kPa, VLI limit |

| Winter | Sales of petrol between 16 Oct and 15 April | 70-100 kPa |

Whilst a range of volatility is allowed with each season, the reality is that due to manufacturing limitations and production cost issues, the volatility will always be close to the upper limit in the summer and winter from all suppliers.

The lowest volatility petrol is available in the UK summer between 1 June and 31 August. The transition to summer grade depends on the fuel supplier logistics and service station throughput volume. It typically takes 3 deliveries to a service station of low volatility summer grade petrol to meet the maximum summer volatility of 70 kPa. Low throughput service stations do not have to comply with the summer volatility specification if they have not received 3 deliveries by 1 June.

Vehicle operability problems usually occur during the spring and autumn periods on warm days where high volatility fuel is still in the market as the VLI requirement does not protect against vapour lock in more severe fuel systems. With many historic vehicles fuelling with super unleaded (E5) fuel to be known as the protection-grade from September 2021, it is important to purchase the fuel from a high turnover service station to ensure the lowest volatility is available at the pump.

The view expressed by some, that the solution is to add kerosene to the blend, was examined in some detail, but is not generally supported by the Federation on the basis that dilution of the petrol with a higher boiling component such as kerosene will not remove the high volatility components but dilute them. Although this can help reduce vapour locking in some circumstances, the addition of a higher boiling component such as kerosene will increase exhaust emissions and cause dilution of the lubricating oil in the oil sump with unburned kerosene with its implications for increased engine wear rates. There are more effective ways to deal with the problem.

Nonetheless, in 1991 the Federation obtained a general licence from HM Customs & Excise permitting the addition of rebated kerosene to fuel in the tanks of pre-1940 vehicles. A section discussing this aspect in more detail is included towards the end of the topic on fuels, for those who wish to read more on the subject.

The Federation has published detailed information about simple practical steps which can be taken to overcome problems such as vapour lock, which stem from the volatility of today’s petrol when used in some historic vehicle fuel systems. An updated summary of the recommendations is given below:

- Reduce the flow of (exhaust) heat to the liquid fuel supply to the engine

- Route fuel lines away from heat sources

- If possible arrange for a smaller diameter return fuel pipe from the carburettor feed to the fuel tank. This will help to ensure cool fuel from the tank is always available at the carburettor. This is particularly important after the vehicle has stopped after a run, as heat soak from the engine will warm the stagnant fuel in the fuel lines. An electric pump is helpful, in that turning on the fuel pump will flush the warm fuel back to the tank prior to starting the engine.

- Locate the fuel pump (eg electric pump) away from heat sources and if possible below the fuel tank to ensure it runs with a positive head on the suction side to limit vapour build up and avoid cavitation.

- Use a thermal break (eg plastic spacer) where possible for mechanical (engine-mounted) pumps

- Shield carburettor(s) from radiant exhaust heat (especially where inlet and exhaust are on the same side of the engine)

- Check radiators for condition and effective dissipation of engine heat. Many old radiators may have become furred-up or partially blocked, leading to significant reduction in their ability to keep the engine cool in traffic.

Often, simple modifications such as these can be extremely effective in preventing the formation of unwanted vapour bubbles in the liquid fuel. Relatively minor changes need not alter the character of a historic vehicle, while thermal baffles and heat shields can be fitted sympathetically to provide minimal visual impact.

Ethanol

The Federation has identified three operational aspects relating to the addition of ethanol to petrol:

-

Compatibility

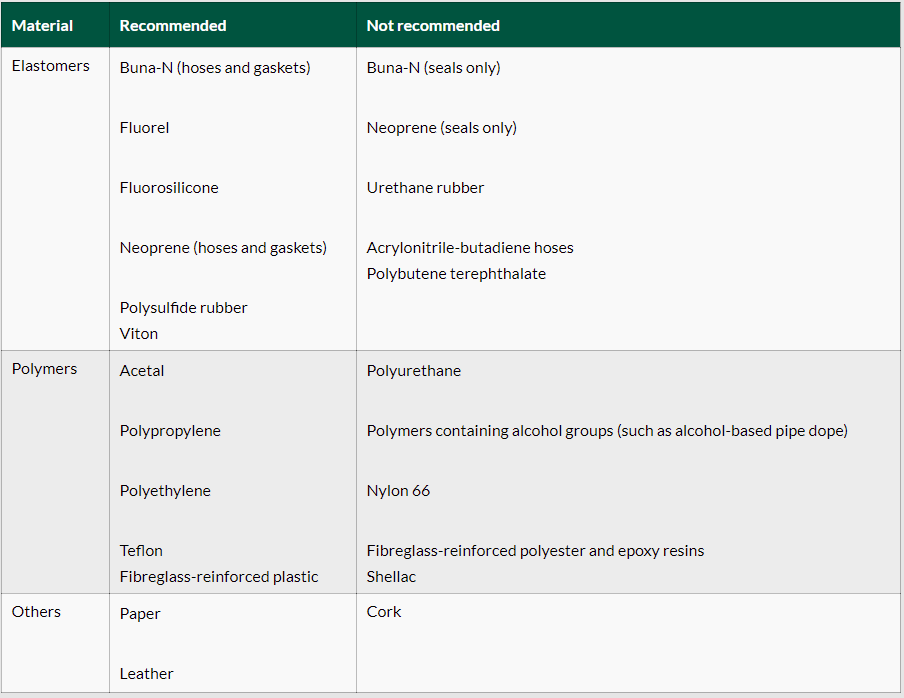

Some elastomers, plastics and composite materials are not compatible with petrol containing ethanol. Where problems are experienced, incompatible materials in the fuel system should be replaced with compatible alternatives.

Acknowledgement and thanks to CONCAWE who provided the above data.

-

Corrosion

Long-term storage of petrol-ethanol mixtures (eg. over a winter period) can lead to corrosion in historic vehicle fuel systems. Following tests, a number of corrosion inhibitor additives which were effective at protecting fuel system metals were identified by the Federation and previously endorsed. The use of corrosion inhibitor aftermarket additives is now well established in historic vehicles and due to the changing nature of individual supplier product formulations, it is no longer possible to provide a listing of endorsed additives.

-

Combustion

There is no evidence that the addition of ethanol to petrol directly affects combustion adversely, but ethanol does have a leaning effect; fuel mixture strength becomes slightly weaker, and this is particularly true for higher ethanol blends. Petrol containing 10% ethanol for example, would result in a mixture-leaning effect equivalent to approximately 2.6%, which may be felt as a power loss, but also could contribute to slightly hotter running. Adjusting mixture strength (enrichment) to counter this problem may prove beneficial. The addition of ethanol to petrol increases the volatility, however this is taken into account when the petrol is manufactured so that the finished ethanol/petrol blend has the same volatility as petrol not containing ethanol and meets the BS EN228 petrol standard requirements. It should be noted however, that switching between ethanol containing petrol and non-ethanol containing petrol will result in the mixture in the fuel tank having a higher volatility, which may cause vapour locking problems and should be avoided if possible.

Matt Tomkins, an associate of FBHVC and Projects Editor of Practical Classics Magazine carried out a study of carburettor component degradation in varying concentrations of petrol/ethanol mixes whilst studying as an undergraduate student at Oxford Brookes University. This study was submitted as his undergraduate thesis and Matt has been kind enough to give FBHVC permission to reproduce it here. You are respectfully requested to respect his copyright of this interesting work.

Introduction of E10 petrol

After an extensive consultation process, the Department for Transport has announced that they will legislate to introduce E10 petrol as the standard 95-octane petrol grade by 1 September 2021. They will also require the higher-octane 97+ ‘Super’ grades to remain E5 to provide protection for owners of older vehicles. This product will be designated as the ‘Protection’ grade.

The introduction of the 95-octane E10 grade and the maintenance of the Super E5 protection grade will be reviewed by the Government after 5 years to ensure they remain appropriate to the needs of the market:

- In relation to the E5 protection grade, such a review will examine market developments over the period.

- HM Government have sought to reassure FBHVC members and historic vehicle owners that, without a suitable alternative becoming available, it is highly likely the Super E5 protection grade would continue to be available.

Filling stations that stock 2 grades of petrol and supply at least one million litres of fuel in total each year will need to ensure one product is the Super E5 protection grade. While not all filling stations meet these criteria, almost all towns across the UK will have a filling station that supplies the ‘Super’ grade and currently one major retailer, a national supermarket group, has committed to offer the product. The main exception to this is in certain parts of the Highlands, north and west coast of Scotland, which will be covered by an exemption process and allowed to continue to market the 95-octane E5 grade.

The Federation therefore recommends that all vehicles produced before 2000 and some vehicles from the early 2000s that are considered non-compatible with E10 - should use the Super E5 Protection grade where the Ethanol content is limited to a maximum of 5%. To check compatibility of vehicles produced since 2000, we recommend using the new online E10 compatibility checker: https://www.gov.uk/check-vehicle-e10-petrol .

It should be noted that some Super E5 Protection grade products do not contain Ethanol as the E5 designation is for fuels containing up to 5% Ethanol. Similarly E10 petrol can contain between 5.5% and 10% ethanol by volume. Product availability varies by manufacturer and geographical location and enthusiasts should check the situation in their location.

Synthetic Fuels

There have been a number of announcements in 2020 with respect to E-Fuels that are hydrocarbon fuels produced from non-fossil sources. Renewable electricity is used to produce hydrogen from water by electrolysis and carbon is captured from the atmosphere (CO2) and combined to produce a liquid fuel. Synthetic fuels have an advantage over conventional biofuels in that they do not compete with food supply or for land use. Whilst synthetic fuels have been produced from fossil hydrocarbon sources over many years and the processes are well understood, these fuels are unlikely to be available in volume for many years to come due to the high levels of renewable electricity required and the difficulty and cost of filtering CO2 from the atmosphere, but do offer the hope that liquid fuels with their high energy density will continue to be available in the future.

Other Fuels

There are many historic vehicles and machines sheltering under the Federation umbrella which use fuels other than petrol. Over the years changes to these fuels have also resulted in the need to adapt in order to ensure their continued operation. Some examples of action by the Federation in respect of these ‘other fuels,’ and the engines on which they operate, are given below.

-

Tractor Vaporising Oil

In 2006, FBHVC looked into the use of Tractor Vaporising Oil (TVO) in tractors. TVO has not been marketed as such since the 1970s, so owners of tractors with spark ignition engines either had to convert to run entirely on petrol (may not always be possible, and is expensive) or create their own TVO using kerosene heating oil.

Not only was this illegal for road use (because kerosene, like 'red diesel', is a 'rebated' fuel on which normal duty is not charged) but because of the way the law is worded, it was also technically illegal to use home-brew TVO in a tractor on private land if that tractor is licensed for use on the road.

FBHVC took this matter up with HM Revenue and Customs, and the result was a special licence allowing members of FBHVC subscriber organisations to mix rebated kerosene with other non-rebated fuels (typically petrol) in the tanks of their tractors. However, mixing with red diesel is not allowed.

A typical recipe for TVO blended from available fuels is one part petrol to one part BS2869 C2 domestic heating oil (kerosene). Use of 2 parts petrol with one part kerosene will produce a higher octane blend.

-

Diesel

The sulphur level of gas oil was reduced from 1000ppm to10ppm as from 1 January 2009. Federation representatives attended stakeholder meetings with the Department for Transport in the run-up to this change, to influence matters where possible, and to ensure that there was a sound knowledge of the changes to come and their possible effects on historic vehicles or machines owned by members of FBHVC subscriber organisations. The change in fuel specification had implications for historic agricultural and construction equipment, and perhaps stationary engines, or historic marine engines running on diesel-type fuel. Tractors run on TVO were not affected but for those with diesel powered historic machines normally using ‘red’ diesel or gas oil, it was felt that the changes in sulphur levels might cause some difficulties.

Lorries and buses should not have been affected as they had already been exposed to the reduction in sulphur levels in on-road diesel fuel. When a sudden change to ultra-low sulphur diesel has occurred in the past, some operators have experienced problems of seal swelling or shrinking, leading to leaks from the fuel system, although this has by no means been a universal experience. These problems are not due to the reduced sulphur content of the diesel but a reduction in the diesel fuel aromatic hydrocarbon content due to the sulphur removal process and lower environmental limits on aromatics.

There have also been some fuel stability issues with lower sulphur diesel fuels and also with those containing bio-diesel components, which have resulted in blocked fuel filters and similar problems.

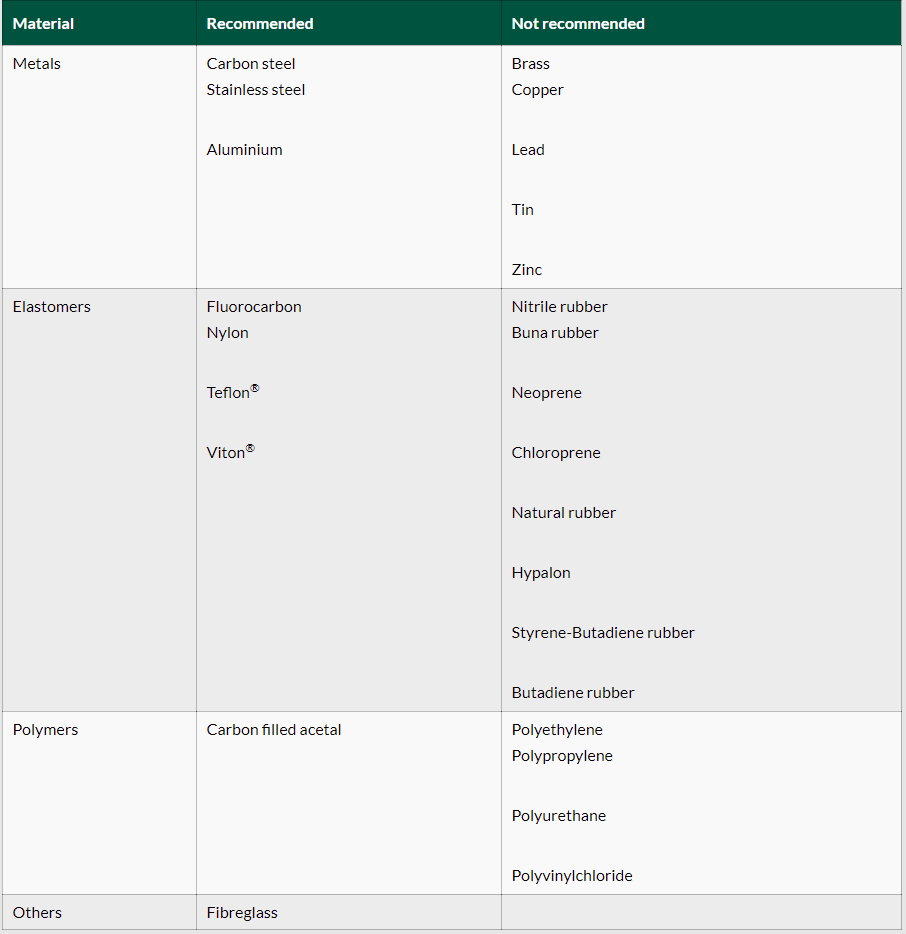

Where fuel leaks occur, new seals should be fitted. These should preferably be made from Viton, as there may also be some potential compatibility problems from the inclusion of bio-diesel components. Viton seals should resolve all these difficulties, and it is obviously preferable to replace seals only once. Fuel filter elements should be replaced to overcome high pressure drop across the filter body which can lead to fuel starvation. Biodiesel is a very strong solvent and can remove accumulated deposits in fuel storage tanks and systems that may result in fuel filter blocking. Filters may therefore need changing more often after the introduction of biodiesel but this should settle down over time as the deposits are removed.

With lower sulphur diesel fuels, particularly those containing bio-diesel, fuel storage is potentially also an issue. Fuels using bio-diesel components have been observed to suffer reduced fuel stability and/or storage life. Fuel composition changes require that fuel housekeeping improves (tanks should be clean and dry, as the presence of water in the tank will encourage microbial growth leading to potential formation of sludges and slimes). Ideally, fuel should be used as quickly as possible, and not stored for lengthy periods. Fuel tank seals, including sight-glass seals, may suffer from the change in aromatic hydrocarbon content and the inclusion of bio-diesel components. These comments apply mainly to those owners such as farmers, who have their own dedicated storage tanks, and who also enjoy the use of historic ‘red diesel’ machinery such as preserved tractors. Red diesel also known as gasoil meets the BS2869 fuel standard in the UK. In many cases these days it is the same as BS EN590 on-road diesel with the addition of marker dye and invisible customs markers designed to prevent duty fraud.

The Federation was able to access the wording of a DfT information leaflet concerning changes to ‘red diesel’ as a result of attending a Stakeholders Meeting in October 2009. This information is reproduced below:

Text of the Department for Transport Leaflet:

Changes in gasoil quality?

Do you use gas oil (‘red diesel’)?

If so, there are changes which you need to know about:

-

- Gas oil for off-road equipment will be sulphur free by January 2011.

- This is needed by cleaner engines fitted in new off-road equipment which will be made to meet stringent new EU emission standards.

- These standards will improve air quality and reduce adverse health and environmental effects.

- Sulphur free gas oil is also likely to contain up to 7% biodiesel content.

- The majority of existing equipment should not have any problems with the new fuel but a few precautions are recommended.

- Affected equipment will include tractors, other agricultural equipment such as combines, construction plant, forklifts, portable generators and boats, but fuel for stationary and heating applications may also be affected.

Off-Road Equipment:

If you own off-road equipment it is recommended that you:

-

- Examine fuel systems following the switch to the new fuel and ensure that any seals or pipes found to be leaking are replaced.

- If you are having older machinery serviced, replace fuel seals and pipes as a precaution.

- Replace fuel filters after the first two to three tankfulls of the new fuel.

Fuel Storage

If you have gas oil storage tanks it is recommended that you:

-

- Remove all water from the tanks and conduct monthly checks so that they remain free of water.

- Tanks used to be fitted with a low point drain and a manual valve. New tanks are no longer fitted with low point drains due to environmental contamination concerns and it is recommended that a stainless steel pipe is installed from the top of the tank extending down to the tank bottom low point to enable water to be removed by means of a suction pump.

- Examine sight gauges on older fuel storage tanks for signs of leakage and replace any leaking seals.

- If you are having tanks serviced before you receive the new fuel it would be advisable to replace fuel seals as a, one-off, precautionary exercise.

- Replace fuel filters after two to three deliveries/turnover of the new fuel.

- Ensure the content of tanks is turned over every six months or in any event no less often than every 12 months to help prevent blockage of filters.

Stationary Equipment

-

- Gas oil for heating, stationary equipment is not required to be sulphur free.

- However, some fuel suppliers may supply you with sulphur free gas oil for these applications as well, in which case the above precautions will be equally applicable.

Marine Fuel

-

- Gas oil sold for inland shipping and recreational craft when used on inland waterways is required to be sulphur free.

- However, gas oil for sea-going marine use is not required to be sulphur free. It is not anticipated that suppliers of marine fuel will switch to sulphur free, but you may wish to confirm this with your supplier.

Further Guidance

-

- Let your fuel supplier know what purpose you need the fuel for. They should supply you a fuel that is fit for purpose and be able to advise you of the sulphur and biofuel content of the fuel.

- Further advice is available on the Department’s website at www.dft.gov.uk .Since the full text is quite lengthy, a summary of the DfT leaflet is given below

Summmary of the DfT leaflet

Key points for Federation members:

-

- Fuel changes are to ‘red diesel’ for off-road equipment: historic trucks and buses already use low sulphur fuels, although they could be affected by inclusion of bio-diesel components.

- Check seals for leaks, both on fuel systems on machines and also on storage tanks.

- Maintain good housekeeping in storage tanks (i.e. drain any existing water from storage tanks and keep them clean, so that only dry fuel is stored).

- Reduce fuel storage periods, ideally to a maximum of six months.

- Check and replace fuel filters after the change to the new fuel.

If you are replacing seals, it is best to use a material which is fully compatible with the new fuel. CONCAWE, a technical association of European oil refiners has produced a report - 9/09 Guidelines for handling and blending FAME that provides advice on biodiesel materials compatibility. The following table extracted from the report was issued at the Stakeholders’ Meeting. It covers blends of diesel fuel containing bio-derived components. The most universally recognised compatible seal (elastomer) material is known by the trade name ‘Viton®’. Other seal materials e.g. Nylon, Teflon® and Fluorocarbon are also recommended for use with the new fuel.

Material compatibilities with bio-diesel and diesel blends

CONCAWE comment: This list is not comprehensive and the quality of the material must be appropriate for the intended application.

Operating problems and supplementary information

Operating problems with historic vehicles after the disappearance of ‘two star’ leaded petrol began to be reported in significant numbers in the early 1990s. Some believed that higher octane ‘four star’ petrol could not be safely used in older low compression engines, resulting in some enthusiasm for the addition of kerosene to petrol for use in historic cars, in order to reduce octane quality. This line of argument has been overturned, and in fact it is now generally accepted that while ‘excessive’ octane quality might be a waste of money, it is not harmful in low compression engines. The alternative view, that the greatly increased volatility of modern petrol is to blame for operating problems in older engines, is widely accepted.

With this in mind, there was a renewal of interest in the addition of kerosene to petrol. Kerosene has a boiling range from about 160°C to about 250°C, whereas petrol boils over the approximate range 30°C to 200°C. Problems experienced in older engines, such as overheating, power loss, poor hot starting etc. have been attributed to the increased proportion of low boiling material added to petrol in more recent decades. This is believed to result in vapour formation in the wrong places, thereby upsetting fuel-air ratios, and in the main, causing enleanment of fuel-air mixtures reaching the combustion chamber. Addition of a high boiling material such as kerosene does not affect the ‘front end’ of the fuel in the sense of preventing low boiling-point hydrocarbons in the fuel from vaporising (low boiling point hydrocarbons in the fuel will boil off and form vapour long before the kerosene starts to boil), but if kerosene is added at 5% or 10% by volume for example, the proportion of the ‘front end’ components will be reduced by a corresponding amount, and this may be just enough in some engines to alleviate the negative effects of potentially excessive vapour formation. Some owners of historic vehicles report significant benefits from the use of kerosene in this way.

However, the high ‘back end’ boiling temperatures associated with kerosene should not be overlooked. Problems can arise in engines not adapted specially to burn kerosene-based fuels (eg tractors designed to run on TVO). Use of petrol containing significant amounts of kerosene may result in incomplete combustion, since a fuel which has not completely evaporated will not burn. Any unburned material will find its way into the sump where it will dilute the lubricating oil. A significant amount of diluent derived from kerosene addition in the lubricating oil would run the risk of lubrication problems, with consequent increased wear of bearing surfaces. The use of kerosene (TVO) blends in historic agricultural tractors has been cited as a reason to support the use of similar fuels in historic vehicles, particularly as some of these machines use car-derived engines. However, in order for these machines to burn kerosene-blend fuels efficiently, a special vaporising inlet manifold was used on the tractor version, to ensure that complete combustion occurred, without the risk of oil dilution. The same engine in a passenger car, if operated on kerosene-blend fuels, will not be so well suited to these blends.

Kerosene addition is likely also to increase the risk of deposits in the fuel system, and may also increase the formation of sooty particulates in the exhaust gas. Overall, while it acknowledges that some historic vehicle owners have suffered from poor engine operation with modern petrol, the FBHVC does not feel able to recommend the use of kerosene in petrol in older vehicles. Instead, the Federation endorses the recommendations contained in a booklet published by the Vintage Sports Car Club, entitled ‘Fuel Problems – Use of Modern Petrol in Older Engines’ some years ago. As this booklet was published some years ago copies are no longer available, however the VSCC library does retain a copy and scans may be available by arrangement.

These recommendations are felt to address the causes rather than the symptoms of the problem, and are still relevant today.

The following suggestions are made in the report:

- Adoption of local solutions to reduce heat input to the fuel system, principally from hot exhaust components

- Use of insulating gaskets or other thermal breaks between fuel pump and engine and/or between carburettor(s) and inlet manifold

- Use of heat shields to prevent heat being radiated from the exhaust system to the carburettor(s) and other fuel system components

- Careful routing of fuel feed lines away from sources of heat from the tank to the carburettor(s)

These suggestions will be of most value in engines where the inlet manifold and the exhaust manifold lie on the same side of the engine. Engines where carburettors and exhaust are on opposite sides of the cylinder head tend to be much less affected by volatility related problems.

In addition, the condition of the radiator in water-cooled engines should not be overlooked. Old radiators can become really quite inefficient over time with accumulation of scale, debris and sludge on heat transfer surfaces, but the process can be slow and may not be noticed. Chemical flushing can improve cooling efficiency, but in some cases a replacement radiator core may be the best way to restore efficient operation.

Additional information on Octane

Petrol octane is a measure of a fuels resistance to knock. Octane requirement should therefore be seen as a minimum requirement to ensure the correct operation of the engine.

In the 1920s the Cooperative Fuels Research (CFR) Committee was formed to respond to the need of refiners and engine builders to develop a means of measuring and defining petrol combustion characteristics.

Today’s octane scale was proposed by Graham Edgar in 1926, established in 1929 and has been used ever since:

- Two paraffins of similar physical characteristics selected as standards:

- iso-octane (2, 2, 4 trimethylpentane) defined as 100 octane

- n-heptane was assigned a value of zero octane number

Hence a volume blend of 95% iso-octane and 5% n-heptane has an octane number of 95.

The octane number of a fuel is the % volume of isooctane in a blend with n-heptane that shows the same antiknock performance as the test fuel when tested in a standard engine under standard conditions.

In 1928 the CFR Committee decided that a single cylinder test engine was needed as a first step in developing a petrol knock test method. In early December 1928, the CFR Committee accepted the basic Waukesha Motor Company design and the first engine was constructed in 1929 to measure road fuel octane numbers based on the Edgar octane scale.

During the 1930s it was found that it was not possible to correlate the performance of cars on the road with just one type of octane number because engine designs and driving conditions were constantly changing. The Motor Octane method was subsequently developed and introduced to address higher speed and load conditions.

There are two key measures of octane quality:

• Research Octane Number (RON) – Moderate speed cruising and acceleration. Mild operation

• Motor Octane Number (MON) High engine speed, high load. Severe operation.

Different engine designs have different RON and MON requirements but in general for classic and historic vehicles both RON and MON are important. Modern direct fuel injection engines have been found to be mostly RON sensitive. This is probably due to the in-cylinder cooling effects of direct injection and stratified fuel mixtures.

In Europe RON is posted on service station dispensing pumps whereas in the USA (RON+MON)/2 is posted, hence the apparent lower octane numbers. A European unleaded 95 grade has a minimum RON of 95 and a minimum MON of 85 which would be posted as (95+85)/2 = 90 in the USA.

The higher octane Super E5 Unleaded protection grade in the UK has a minimum RON of 97 and a minimum MON of 86 which matches the old leaded grade (BS4040). In mainland Europe the Super Unleaded grade has a minimum RON of 98 and a minimum MON of 86. A number of Super Unleaded grades are also available with a minimum RON of 99 and a MON of 86 in the UK market.

Troubleshooting hints and tips

Observed problem of overheating in two-stroke engines operating on fuel containing ethanol:

Operating two-stroke engines on petrol containing ethanol will result in enleanment of the fuel-air mixture and can cause overheating resulting in piston and piston ring scuffing and engine failure due to reduced operating clearances. Higher operating temperatures can also lead to higher piston and piston ring groove deposits that can also cause piston ring stick and piston scuffing. These engines are usually equipped with carburettors and ideally should be adjusted to enrich the mixture and hence lower engine operating temperatures. Adjustment may mean re-jetting and manufacturers should be contacted for advice.

It is also very important to use high-quality two-stroke oil capable of protecting the engine at high temperatures that produce less engine deposits and enhanced lubrication. Always observe the manufacturers recommendations on mixing ratios for optimum protection and low-smoke emissions.

From a fuel perspective, some manufacturers in Scandinavia and other European countries are marketing small quantities (5 litre cans) of an alkylate petrol that does not contain ethanol and has a high octane.

Alkylate is a mixture of branch-chain paraffins with a high octane and is produced by combining light hydrocarbons from refinery catalytic cracking (propenes and butenes) with isobutane in the presence of a strongly acidic catalyst. Alkylate is widely used as a high octane blend component in modern petrol and was used extensively in the Second World War to manufacture high octane aviation petrol for military use. Alkylate burns very cleanly with low engine deposits and is favoured for handheld equipment such as chainsaws and is also a key component of aviation gasoline (Avgas). There is currently a proposal to develop a European CEN fuel standard for alkylate petrol as there can be issues with the manufacturing process resulting in contamination that can cause problems in engines. Alkylate petrol will remain a low volume petrol product and is primarily aimed at the small engine market.

Problems with incompatibility of petrol containing ethanol with fibreglass fuel tanks

The Federation received a significant number of reports of damage to fibreglass fuel tanks fitted to some historic motor cycles after the introduction of ethanol into petrol during 2008. Involvement in Stakeholder Meetings at the Department for Transport in 2009 featured this problem, and also highlighted the table from CONCAWE featuring compatible and incompatible materials, which is shown in the section on ethanol fuels. Further discussion led to investigation into the legal position on the use of fibreglass fuel tanks for motor cycles.

The following is a statement about fibreglass fuel tanks from the Construction and Use Regulations:

• Regulation 39(2)(c) of The Road Vehicles (Construction and Use) Regulations requires all petrol tanks on vehicles first used after 1 July 1973 to be metal. This applies to all vehicle types. There are no requirements on the material of diesel tanks.

The only exemption from the requirement for road vehicles is for vehicles with fuel tanks approved to Directive 70/221/EEC or EC.

Downloads

| FBHVC_News_Issue_4_2019 p8.pdf | |

| E5 Petrol Guide.pdf | |

| Essential Guide to Fuels v3 2023.pdf | |

| Matt Tomkins Dissertation. Effect of ethanol conc in petrol on carburettor components.pdf |